NASA Uses Twin Processes to Develop New Tank Dome Technology

$ 8.50 · 4.6 (739) · In stock

(PhysOrg.com) -- NASA has partnered with Lockheed Martin Space Systems in Denver, Colo., and MT Aerospace in Augsburg, Germany, to successfully manufacture the first full-scale friction stir welded and spun formed tank dome designed for use in large liquid propellant tanks.

(PhysOrg.com) -- NASA has partnered with Lockheed Martin Space Systems in Denver, Colo., and MT Aerospace in Augsburg, Germany, to successfully manufacture the first full-scale friction stir welded and spun formed tank dome designed for use in large liquid propellant tanks.

NY's fossil fuel use soared after Indian Point nuclear plant closure

Polymath: The Coming SSTO's: multi-Vulcain Ariane.

Michoud Assembly Facility – Just another NASA Blogs Sites site

Mars 2020 Descent Stage in the Spacecraft Assembly Facility at

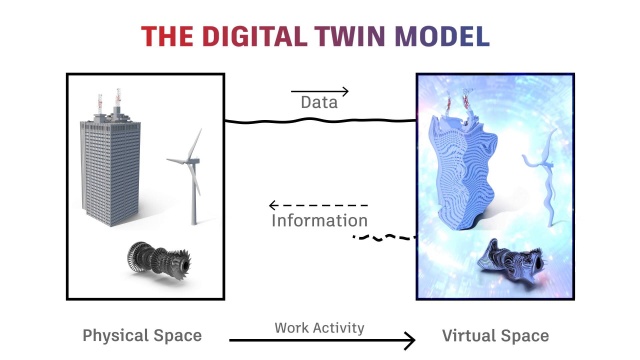

What is a digital twin, and how does it work?

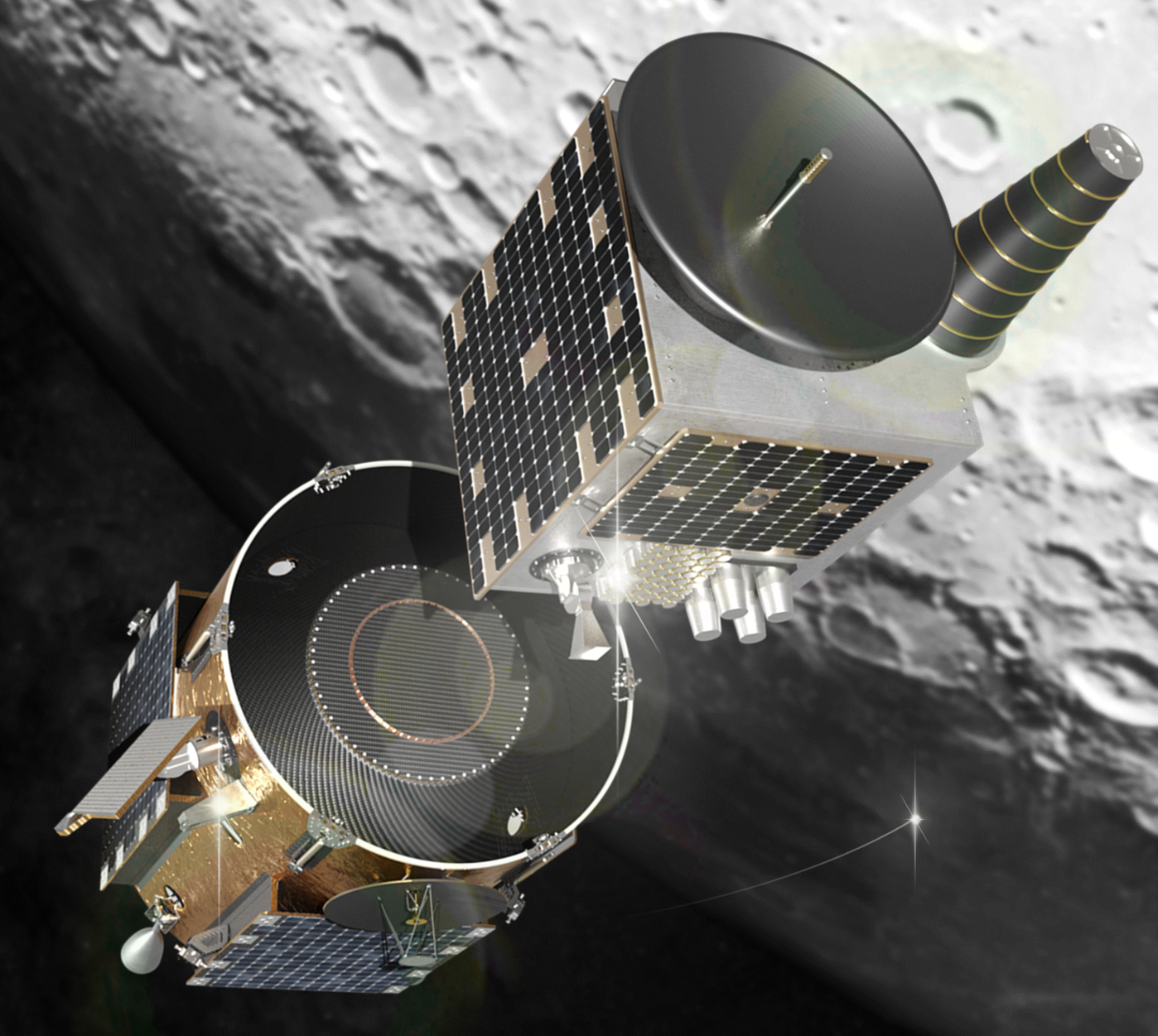

NASA selects Firefly Aerospace for lunar surface payloads

Schematic representation of laser powder bed fusion (credits NASA

No Shortage of Dreams: Space Shuttle External Tank (ET

NASA/Boeing composite launch vehicle fuel tank scores firsts

New welding discovery could radically improve manufacturing practices

Large Aperture Inflatable/Deployable Antennas and Their Role in

Boeing all-composite cryogenic fuel tank proves technology